In the field of material science, impact testing is important as it helps experts evaluate the strength and resilience of materials under real-world scenarios. One method used in impact testing is the IZOD test. In this article, we will delve into how IZOD impact testing is applied in material science and its role in aiding decision-making for material selection.

Understanding IZOD Impact Testing

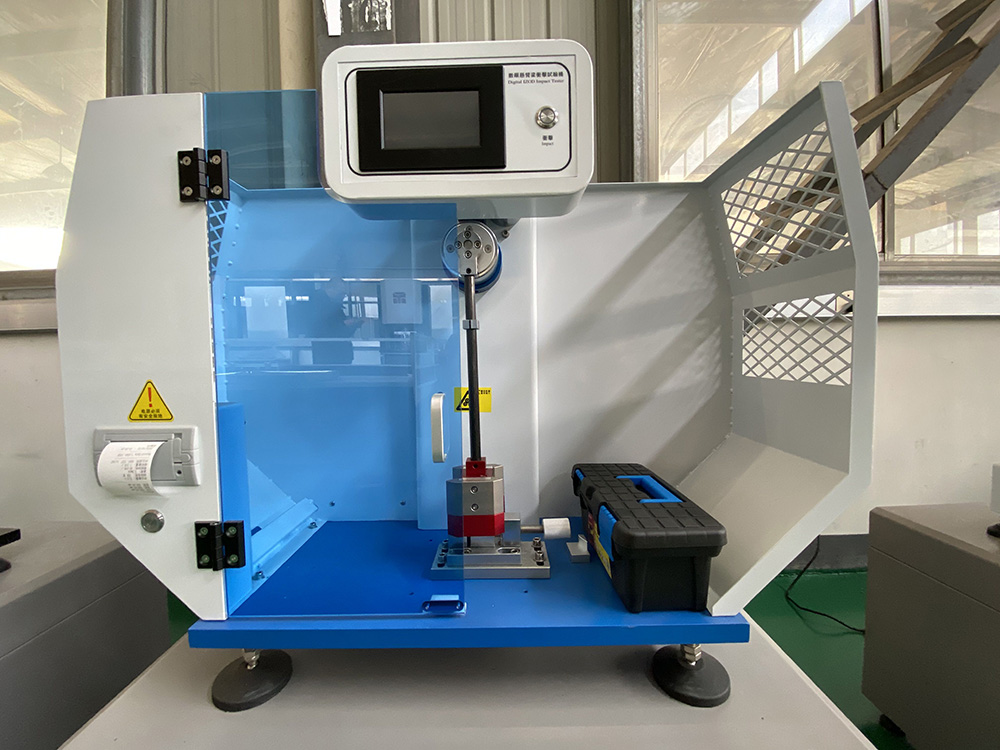

IZOD impact testing, utilising the IZOD impact tester, is a procedure for determining a material’s ability to withstand impacts or blows. This test involves striking a notched sample with a hammer to measure the energy absorbed during fracture. By conducting this test, researchers can assess how effectively a material can endure forces by measuring its energy absorption capacity without breaking.

Assessment of Material Toughness

Material toughness signifies its capability to absorb energy before fracturing, which’s crucial in determining if a particular material is suitable, for its intended use. Through IZOD impact testing researchers can precisely evaluate this toughness attribute by quantifying the energy absorbed during fracture.

For example, strong polymers commonly used in applications like car bumpers or protective covers undergo IZOD impact testing to ensure their ability to withstand impacts, such as collisions or falls. By testing these materials in controlled settings that replicate real-life scenarios, researchers can determine if they have the toughness for their intended uses.

Understanding How Materials Break

IZOD impact testing also helps in understanding how different materials break when they experience a force. Depending on their structure and atomic bonding, materials can show either ductile or breaking behaviour.

Brittle materials tend to break when pushed beyond their strength limit with deformation before they shatter. In contrast, ductile materials show plastic deformation before failure due to the rearrangement of atoms within the material’s structure.

By studying breaking patterns in IZOD impact tests, scientists can identify the type of breaking behaviour a material displays. This knowledge is crucial for selecting materials for applications where either brittle or ductile behaviour is preferred.

Choosing the Right Materials

One use of IZOD impact testing is assisting engineers and manufacturers in choosing the materials for their products or structures. By subjecting materials to this test, they can compare how well different materials absorb energy.

This method helps determine which materials offer the level of strength and durability needed for a particular use. Take metal fabrication in construction projects, for instance. Contractors must ensure that the metal alloys chosen have resistance to impact when building structures like buildings or bridges that withstand winds, earthquakes, or accidental crashes. The IZOD impact test aids engineers in assessing metal alloys and selecting the suitable one with characteristics that match their project needs.

Maintaining Quality and Meeting Standards

The IZOD impact test is also crucial for quality control during manufacturing processes aimed at creating lasting products. Manufacturers often follow established standards, such as those set by ASTM International or their international equivalents, to ensure quality across their product ranges.

By incorporating IZOD impact tests at production stages, manufacturers can confirm whether the materials produced meet industry standards for toughness. Consistent testing guarantees that only materials meeting the criteria are used for processing or made available to consumers.

Expanding Beyond Manufacturing

The applications of IZOD impact testing go beyond the manufacturing industries and encompass fields like aerospace, medical devices, sports equipment, electronics, and others where safety is paramount.

For example, the aerospace sector uses IZOD impact testing to assess the durability of materials applied in aircraft parts like wings, fuselage structures, and tail assemblies. By subjecting these composites to tests, their strength is confirmed to withstand challenging conditions such as sudden pressure changes, bird collisions, or turbulent flights without compromising passenger safety.

Summary

IZOD impact testing allows scientists, engineers and manufacturers to evaluate material toughness, fracture characteristics and suitability across sectors. The insights gained from these evaluations assist in making informed choices when selecting materials for use. Whether it involves designing components or constructing resilient buildings, the significance of IZOD impact testing in ensuring safety and longevity cannot be overstated. By following established testing procedures, like IZOD, impact testing industries can uphold top-notch standards of quality and dependability in their material selections.